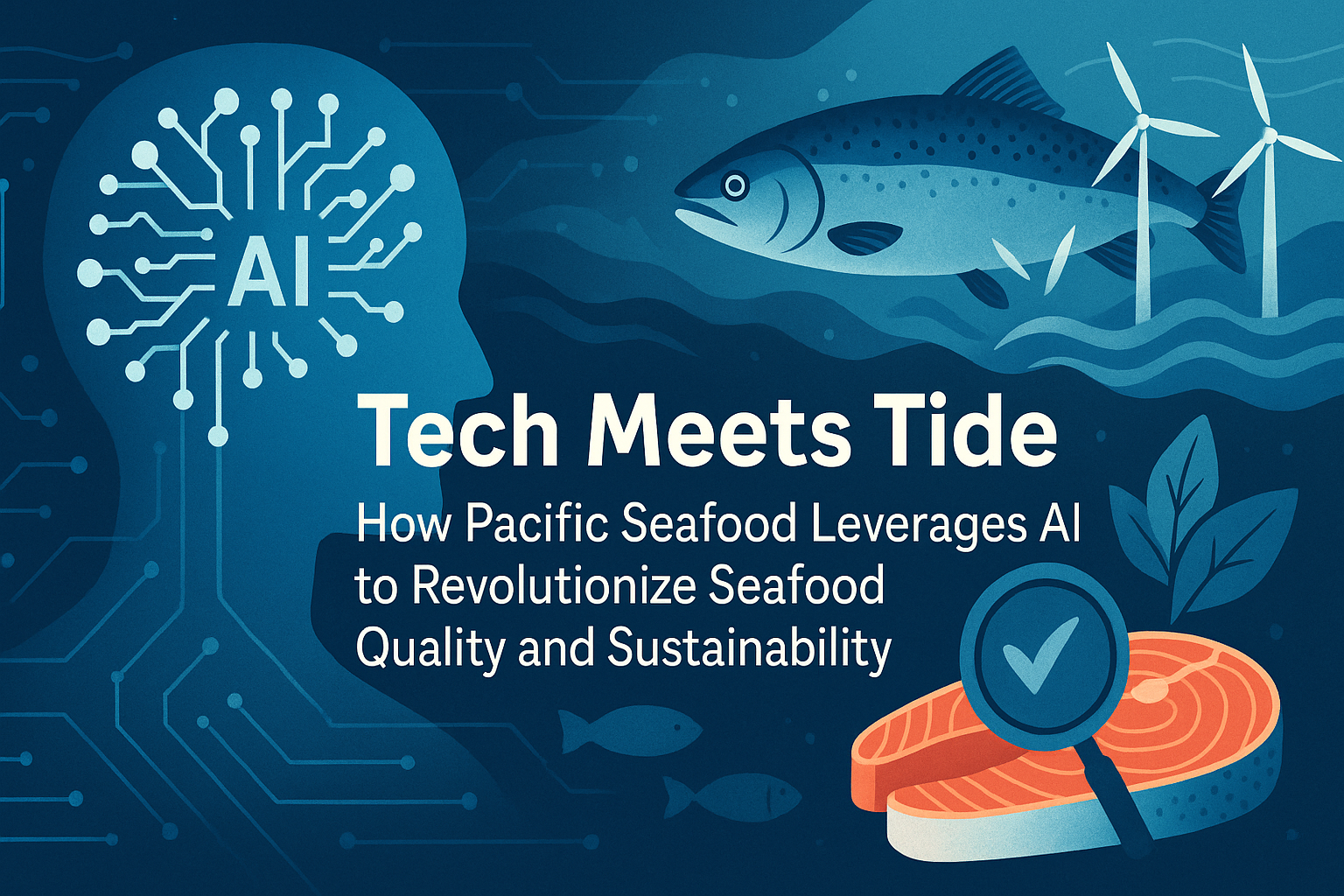

Tech Meets Tide: How Pacific Seafood Leverages AI to Revolutionize Seafood Quality and Sustainability

In an era where technology is transforming traditional industries, Pacific Seafood is pioneering a new approach to seafood production by integrating cutting-edge artificial intelligence (AI) technologies to enhance product quality, improve operational efficiency, and advance sustainability goals.

The company’s innovative strategy demonstrates how advanced technology can address critical challenges in the seafood industry, from workforce training to waste reduction and supply chain transparency.

Technological Innovation at the Forefront

Pacific Seafood, a family-owned enterprise with a rich history dating back to 1941, is proving that technological innovation and sustainable seafood production can go hand in hand. By strategically implementing AI-powered solutions across multiple operational domains, the company is setting a new standard for technological integration in the seafood sector.

Workforce Training Revolution

One of the most significant technological investments is the company’s partnership with Schoox, an AI-powered learning platform designed to transform employee training and engagement. This initiative aims to upskill the company’s 3,000+ team members across 41 facilities in 11 states, creating a more knowledgeable and adaptable workforce.

The Schoox platform leverages artificial intelligence to:

- Personalize learning experiences

- Track employee skill development

- Increase training engagement

- Optimize workforce capabilities

Advanced Traceability and Quality Control

Pacific Seafood has implemented sophisticated traceability software that enables unprecedented transparency in seafood production. This technology allows the company to track seafood products from their origin in the ocean to the final market, ensuring:

- Rigorous quality control

- Enhanced food safety

- Complete supply chain visibility

- Verification of sustainable sourcing practices

Sustainability Through Technology

The company’s commitment to sustainability extends beyond tracking. By utilizing AI and advanced technologies, Pacific Seafood is making significant strides in waste reduction and environmental stewardship.

Waste Reduction Strategies

Through innovative processing optimization technologies, the company is minimizing seafood waste and maximizing resource efficiency. Programs like FishTown® and SeaTea™ transform seafood byproducts such as bones and shells into nutrient-rich fertilizers, demonstrating a circular economy approach to production.

Key waste reduction achievements include:

- Optimized processing techniques

- Conversion of seafood byproducts into organic fertilizers

- Reduced environmental impact

- Enhanced resource utilization

Industry Impact

Pacific Seafood’s technological approach reflects broader industry trends toward digital transformation. By embracing AI and advanced software solutions, the company is positioning itself as a leader in technological innovation within the seafood production landscape.

Competitive Advantages

The integration of AI technologies provides Pacific Seafood with several competitive advantages:

- Enhanced operational efficiency

- Improved employee training and retention

- Superior product traceability

- Reduced waste and environmental footprint

- Data-driven decision-making capabilities

As part of its Mission 31 objectives, Pacific Seafood continues to explore and invest in emerging technologies. The company remains committed to leveraging AI and innovative solutions to address challenges in seafood production, sustainability, and workforce development.

Conclusion

Pacific Seafood’s strategic embrace of artificial intelligence represents more than just a technological upgrade—it’s a comprehensive approach to reimagining seafood production. By combining cutting-edge technology with a long-standing commitment to sustainability and quality, the company is charting a course for the future of the seafood industry.